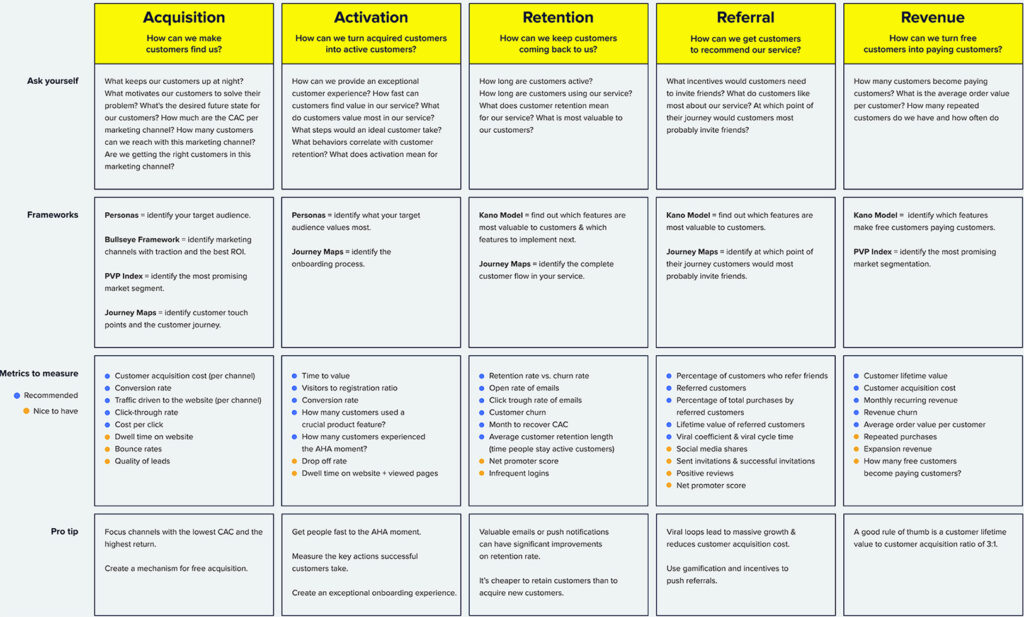

AARRR Framework

AARRR is accepted as the 5 most important metrics for a startup to focus on. These metrics effectively measure your company’s growth while being both simple and actionable.

AARRR stands for the 5 phases in your customer life cycle. These are:

• Acquisition: Where are customers coming from?

• Activation: How to turn acquired customers into active customers

• Retention: How to make potential customers come back

• Referral: How to get customers to recommend your service

• Revenue: How to turn potential customers into paying customers

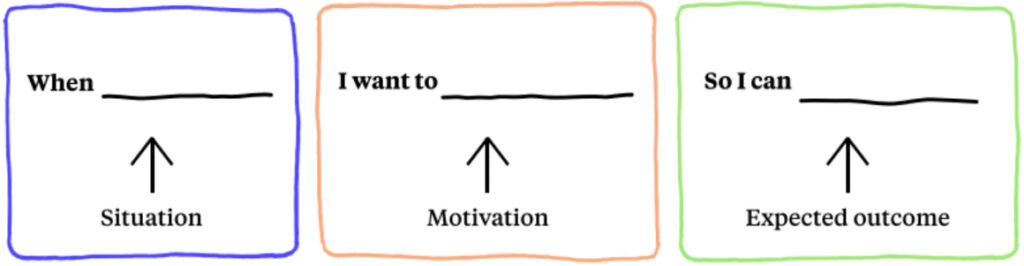

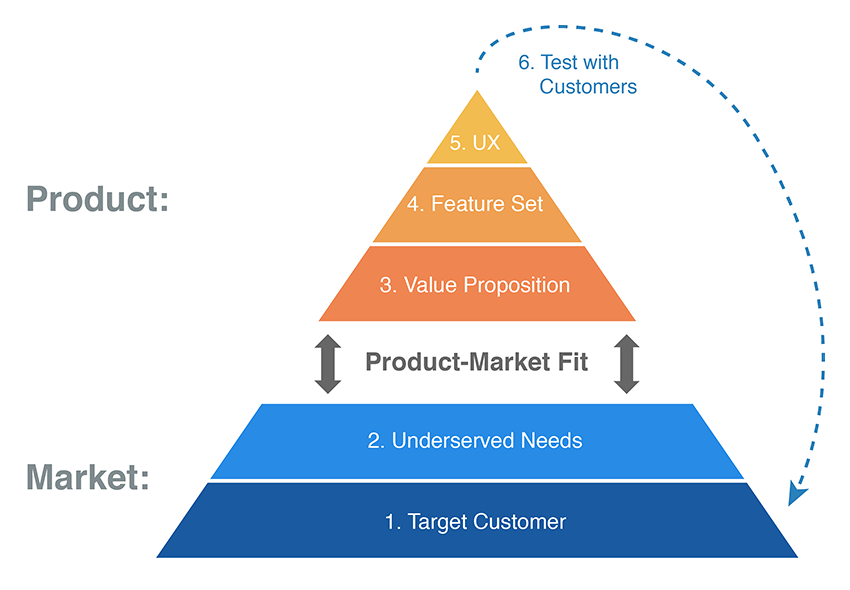

Who are your customers?

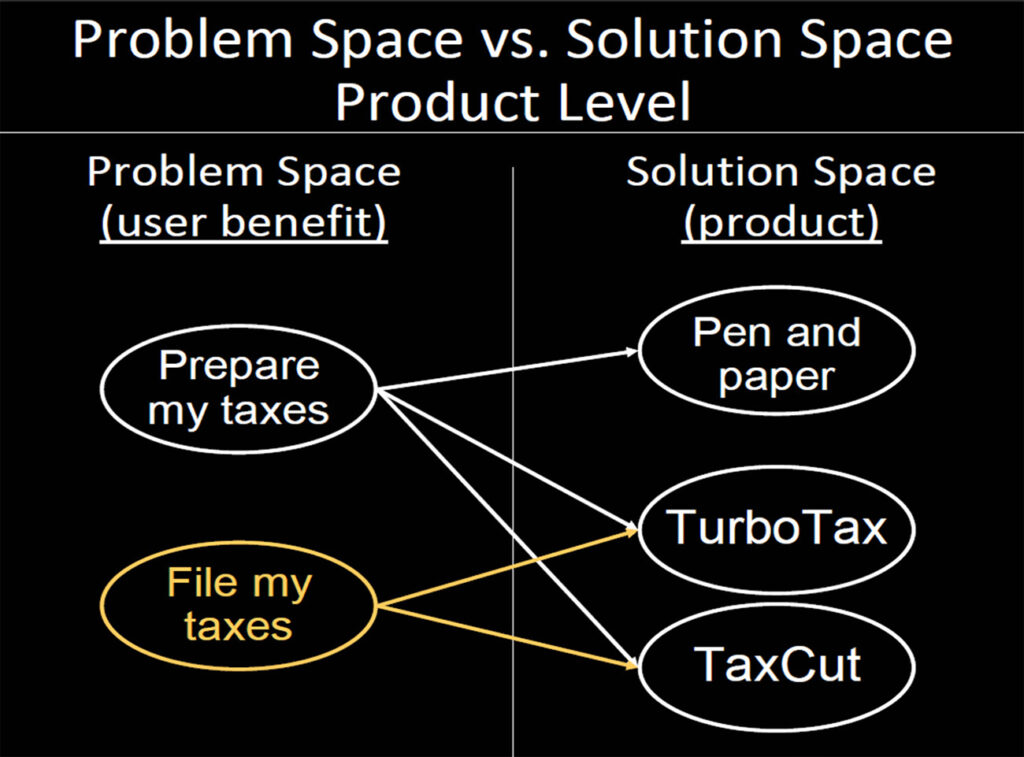

If you want to craft a great solution, you need to know your customers. Do not start by creating a product for everyone – instead focus on specific buyer personas.

To discover more about your target group, ask these powerful questions:

• What keeps my customers up at night?

• What motivates my customers to solve their problem?

• What’s the desired future state for my customers?

Acquisition

Activation occurs when a person becomes an active user. A user may download an app, but if they never use it again, they haven’t been activated.

Driving traffic is important, you should also conduct A/B tests with your landing page tests to determine what brings the best conversion results.

Track user behavior to determine what makes a user commit to your product.

Activation

Your users need an aha moment — the instant a user realises your product delivers meaningful value and makes them want to come back. If a significant percentage of users are not activating – create an onboarding strategy to educate and hand hold users through the initial phases of achieving their goals with your solution is one way to increase activation.

Retention

To reduce churn, you need a solid retention strategy. Beyond creating a valuable product, it’s also critical to keep in touch with your customers.

Automated emails are a simple retention strategy. Create email campaigns to automatically send at various intervals after sign-up. This helps remind your customers of your product and how to use it.

Grammarly sends weekly personalised emails to share users’ writing stats, eg their most common writing mistakes and level of accuracy

Referral

Referral is just one of the many acquisition channels. When someone likes your product enough to tell others, thats the best sign that you’ve created something of great value and people are ready to pay for it.

User recommendations is one of the most effective ways to acquire new customers. According to a Nielsen study, 83% of people trust recommendations from friends and family, and 66% of people trust consumer opinions posted online.

Revenue

One of the most important success metrics is customer lifetime value. The metric describes the total revenue generated by a customer over their lifetime.

To Calculate the customer lifetime:

Customer Lifetime Value = Average revenue per customer * (1/churn rate)

If your average monthly revenue per customer is €100 and your churn rate is 5%, this means that your customer lifetime value: (100 * (1/0,05) = €2000.

Another approach to CLV…

Customer Lifetime Value = Average monthly revenue per customer X (# months) customer lifetime = ($) LTV

Customer lifetime value vs customer acquisition cost

A benchmark is a customer lifetime value to customer acquisition ratio of 3:1.

To find the channel with the lowest CAC and the highest return, apply the Bullseye Framework, which you apply during the acquisition phase.